Top 10 Best Bandsaw For Knife Making : Reviews & Buying Guide

As an Amazon Associate I earn from qualifying purchases.

Bandsaw For Knife Making Purchasing is not an easy task to do. Different manufacturers are introducing hundreds of Bandsaw For Knife Making in the market which can make you puzzled. In terms of performance, quality, longevity, and overall user experience that you may find it difficult to make a final purchasing decision. At that point, all you need is a good buying guide to help you find the best Bandsaw For Knife Making for your needs.

In this useful article, we will discuss a few important factors to consider before purchasing a Bandsaw For Knife Making. You can think of it as a proper review guideline for you, covering the pros and cons of your desired product, such as its sustainability, affordability, functions, and practical benefits. Another feature will be a thorough comparison of a few similar products. As a result, you can easily pick the best one for your demands. Let’s take a look at it from the inside.

Best Bandsaw For Knife Making : Top 10 Picks

Last update on 2025-10-05 at 00:45 / Affiliate links / Images from Amazon Product Advertising API

10 Best Bandsaw For Knife Making’s – Expert Recommended

We tried to determine the top ten Bandsaw For Knife Making from hundreds of products in this section. This list will make you feel assured that you will be able to acquire your desired Bandsaw For Knife Making in a matter of minutes. We emphasized their usefulness, performance, durability, outlook, affordability, and previous user experiences. We are sure that this top 10 Bandsaw For Knife Making list will help you in finding the perfect one that matches your requirements.

- Ferreyra, Gonzalo (Author)

- English (Publication Language)

- 160 Pages - 12/07/2021 (Publication Date) - Cedar Lane Press (Publisher)

- Ultimate Cutting Capacity: This metal band saw features a powerful 10 Amp motor with a 5-inch cutting capacity, allowing you to tackle both large and small metal projects effortlessly, whether for heavy-duty workshop tasks or DIY jobs at home.

- Adjustable Cutting Speed: With an adjustable cutting speed range from 137 to 472 FPM, this saw is perfect for different materials and cutting requirements. Whether you need fast cuts or precise slicing, this tool adapts to your needs with ease.

- Dual Workbench Design: Equipped with a large workbench, this band saw provides a stable platform for cutting large materials. Additionally, the small precision workbench allows for intricate cuts on smaller pieces, offering versatility for all your cutting needs.

- Durable and Safe Operation: Powered by a 10A motor, this metal saw is built to last and handle tough metal-cutting jobs. Safety features such as eyeshield ensure secure, reliable operation

- Ideal for Workshop and DIY: Whether you are a professional in the workshop or a DIY enthusiast in your garage, this band saw is designed to meet all your cutting needs. It’s the ideal tool for metal cutting, offering power, precision, and ease of use for a variety of applications.

- Mark Duginske (Author)

- English (Publication Language)

- 200 Pages - 04/01/2014 (Publication Date) - Fox Chapel Publishing (Publisher)

- Mark Duginske (Author)

- English (Publication Language)

- 200 Pages - 06/03/2025 (Publication Date) - Fox Chapel Publishing (Publisher)

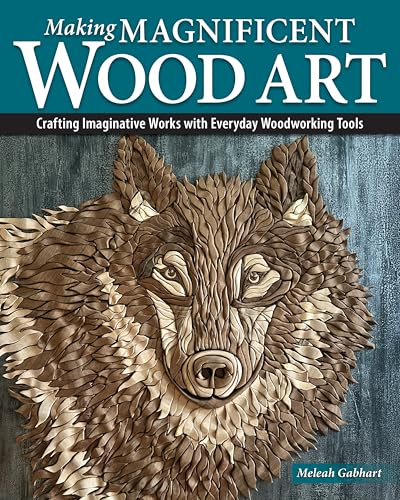

- Meleah Gabhart (Author)

- English (Publication Language)

- 128 Pages - 11/04/2025 (Publication Date) - Fox Chapel Publishing (Publisher)

- COMPATIBLE MODELS: Designed to fit most standard size #32 meat replacement blade models #32, E-2732, 342, 346, 548, 6642, 7542, 7548, AFMG-48-2, 542, 7500, TCA32, TM32/232, A42, 510, 30, 41, 432, 1041, 1541, 2532, 341, 2632, 2732, 2742, 2746, 2842, M32S, 842D, 3028, 5932, 6142, 6832, 6942, 8142, 528 Globe, 4046, 4145, 4146, 4241, 4245, 4246, 4322, 4332, 4342, 4346, 4531, 452, 4542, 4632, 4732, 5425, MC-46, MG-1532, MG2032, 2-32S, 32S, 150, 175, 542, 1332, GEMINI, 2800, 3800, 4000, 5223, M-32.

- ENHANCES GRINDING EFFICIENCY: Works with brands like Berkel, Biro, Butcher Boy, Chop Rite, Enterprise, Fleetwood, Globe, Hobart, Hollymatic, Sanitary, Toledo, Torrey. This replacement grinder knife is engineered with sharpened raised edges to produce smoother, cleaner cuts for even meat texture. This meat grinder part is ideal for professional and home processing applications.

- HARDENED STEEL CONSTRUCTION: The blade grinder is made from durable, hardened steel with precision-ground edges that maintain sharpness through repeated use, ensuring long-lasting performance and reliable results in high-volume grinding operations with specifications of tip to tip - 3 1/2" - Square hole: .578" hardened steel knife edge.

- EASY TO INSTALL & MAINTAIN: Designed for quick installation and effortless replacement during routine maintenance. The #32 grinder blades can be easily removed for cleaning, ensuring consistent performance and minimal downtime in busy commercial kitchens or butcher shops.

- QUALITY PRODUCT: Manufactured by National Band Saw Company that ensures durable and dependable replacement parts for equipments. National Band Saw is not affiliated with any original equipment or parts manufacturers.

- knife making supplies:include Knife Blade Steel (Unannealed) 1.5 Inch x 11 Inch x 0.12Inch,a Pair Knife Scales (Rosewood)L 120mm W 40mm H 10mm, a Pair Knife scales Rivet (copper) Φ6mm L 35mm.

- Knife Blade Steel:Unannealed is easier to cut, (many buyers complain that annealed Knife Blade Steel is too hard for Angle grinder bandsaw or files)

- 1095 plate is a kind of high carbon steel, which is very suitable for making knives. Our 1095 Steel Flat Stock is not annealed, has low hardness, and is easy to grind and cut.

- Knife Scales wood-This is a kind of high-density hardwood, which is very suitable for making knife handles. Its color and texture are very obvious.

- If you’re just getting started with knifemaking,our Knives Blank kit may be right for you! The surface of the knife blade steel you received is coated with antirust oil. If there is a little rust on its surface, please don't worry, it's just the surface.

- Skills Institute Press (Author)

- English (Publication Language)

- 112 Pages - 01/01/2011 (Publication Date) - Fox Chapel Publishing (Publisher)

- COMPATIBLE WITH BIZERBA MODELS: Direct replacement for Bizerba GSP closed models GSPHI150, GSPHI150-GCB, GSPHI150-SLI and more meat slicer covers. Compatible with OEM part number 38030942000, 38030942001, 38030942002, 38030942003 ensuring a seamless fit and reliable operation for your home and commercial meat slicer.

- PREMIUM SAFETY & PERFORMANCE: Provides a protective shield for slicer blades, enhancing safety in operating your deli counter, commercial and home kitchens. Ideal for food preparation, the meat slicer cover prevents accidents while maintaining high operational efficiency.

- DURABLE ALUMINUM CONSTRUCTION: Crafted from robust aluminum, this knife cover is built to withstand the demanding conditions of busy kitchens. Engineered for long-lasting performance, it stands up to repeated use in high-stress environments.

- EASY TO INSTALL: This meat slicer replacement parts is designed for hassle-free installation with no complex tools required, making it a user-friendly solution for quick, efficient repairs in kitchen appliance tools.

- QUALITY PRODUCT: Manufactured by National Band Saw Company that ensures durable and dependable replacement parts for equipments. National Band Saw is not affiliated with any original equipment or parts manufacturers.

- new, never used

- The product has excellent performance through strict quality control

- Strong quality and durability, fine technology, fine details

- Professional production, strict control, with better performance and more stable quality, to win your trust and support!

- Installation type: Direct replacement

Last update on 2025-10-05 at 00:45 / Affiliate links / Images from Amazon Product Advertising API

What To Consider Before Buying Bandsaw For Knife Making

As a human being you can guess some well but it is quite impossible to know everything well. Being the jack of all trade is not a matter of joke. After go through the byuing the guide this time you may being a less fool from more than purchasing Bandsaw For Knife Making without knowing anything.

Not necessarily you have to be a master on that particular product for purchasing only. Just focus on a few key points that we’ll go over later. Taking those simple considerations into account may make your buying experience more pleasant and straightforward. Let’s jump to the main topic

Be aware of your requirements.

The very first thing you should know is your needs or requirement. If you aren’t aware of your needs, there’s a big chance you’ll spend a lot of money on the wrong things at the wrong time. So, first of all and probably most important, we suggest that you take time to consider your necessities for a Bandsaw For Knife Making. Make a short list of your requirements. This simple task will lead you to simplifying your purchasing process. Only after that you can be assure about your priorities.

Budget Vs Price

Budget is that one issue which you can’t ignore before you decide to purchase anything else. Any amount can be set on the price tag of your desired product. That mainly depends on their brand value and different expences like purchasing raw materials, manufacturing, logistics and other operational costs. The higher quality you demand, the higher amount of money you may have to spend for that. It’s vice versa. And your enlisted Bandsaw For Knife Making couldn’t bypass this universal truth too.

“Cut your coat, according to your cloth”- one of the most popular proverb goes in our society. Fristly, take your wishlist on your hand and search those products on the internet. Check the features and costs carefully.Make a comparison between them and choose one. Now ask yourself that you are capable enough to buy that particular Bandsaw For Knife Making or not? If yes, then you don’t need to think twice. Just Go for it. You may think about the second best option if your answer is no.

Choosing the Best Brand

Most of the time, we are biased toward certain brands due to emotional attachments. But not everytime this practice results get good. However, there’s no denying that depending on well-known brands is a good idea. When you have enough money in your pocket you can easily make yoiur decesion. But remember, not every brand is good for everything. As a result, you must exercise extreme caution when determining whether or not you are selecting the appropriate brand for your specific product.

There are two categories of people in the world. One is completely reliant on a specific brand, while the other is unconcerned. All he requires is the proper product for the price he is paying. May be we are not aware of the category that you belong to.However, there are a few guidelines that may be useful to the both of you when it comes to choosing the right brand for the right product.

- Be sure, you know well about the Brand.

- What others have to say about this brand.

- And what’s the average rating for that brand’s particular product?

- Contrast the features with those of competitors.

- Are you satisfied with the features?

Take a look on the Features Part

Whether you buy it online or offline, the first thing you should check is while buying is the features of Bandsaw For Knife Making. If you want to know about the product clearly, then this is the best way. You will be able to understand, this product is going to meet your demands or not.

This part will help you to identify the differences with others. Then, by using features, you can compare this to similar products. One will gain a better understanding of quality as a result of this work, which will make it easier for us to reach a final decision.

Check the Advantages and Risks

Each product has benefits and drawbacks. It is our duties to carefully examine them out first before buying them. Hence, remain cool because you need to figure out the drawbacks which you demanded from the Bandsaw For Knife Making that you are looking forward to buy. Perhaps another manufacturer created the ideal one for you. Just don’t be too lazy to compare yourself to them before making a final decision.

The part of Pros and Cons can be found on most websites. Read that part with care. If you have any further questions, you can contact them via email or phone.

Quality and Endurance

Color, Style, Performance, Materials, and, most importantly, Durability are all factors that contribute to quality. Before you buy anything, you must check those quality related issues carefully. Don’t you think that you are paying for it? Do you think this Bandsaw For Knife Making is worthy enough against the investment you did? It completely depends on the quality that you are going to experience.

Warranty and Return Policy Are Important

Lots of companies are making products. Good quality products are being maintained by some of them. After then they are letting us know those products through making creative advertisements. Nothing found wrong yet. But here comes the “After Sales Service”. This thing is capable enough to make huge difference and for many, it’s a big deal yeah.

Warranty, gurantee and return policies are those facts which you should never ignore even by mistake. Anything can happen even after purchasing the highest quality product. We know that nothing lasts forever. Still a minimum return of value you deserve from the Bandsaw For Knife Making you will pay for. That’s why don’t forget to be careful at the time of checking policies. Sometimes, there may be some hidden issues which they won’t make you clear with words. One simple thing you can do is to ask their representative about those unintelligible facts and be clear before you buy.

Checking FAQ & Customer Reviews make your task easy

Checking customer reviews and FAQ answers are so savior of time that you can’t understand unless you try it. FAQs are few common questions that were asked frequently by mass people like you and they have been answered as well. On the other hand, you will get a real life experience through the customer reviews in which they share their sotries about the product.

So, checking out these two things, you will get the idea of both. You may find so many answers which might not come to your mind before. You will be able to decide whether this Bandsaw For Knife Making will come handy or not without any hesitaton.

Finally

Afterwards, You should consider the value that the Bandsaw For Knife Making providing you is viable enough against the price you paying for it. Is it enough to make you pleased? Does your demands be fullfilled with that? We guess, that is the fact of great importance.

We hope that you enjoyed the article in which we tried to provide you a proper guideline to help you to buy the best Bandsaw For Knife Making. If this article come useful to you, then nobody can be more happy than us. End of the day, your satisfaction makes us feel happy.