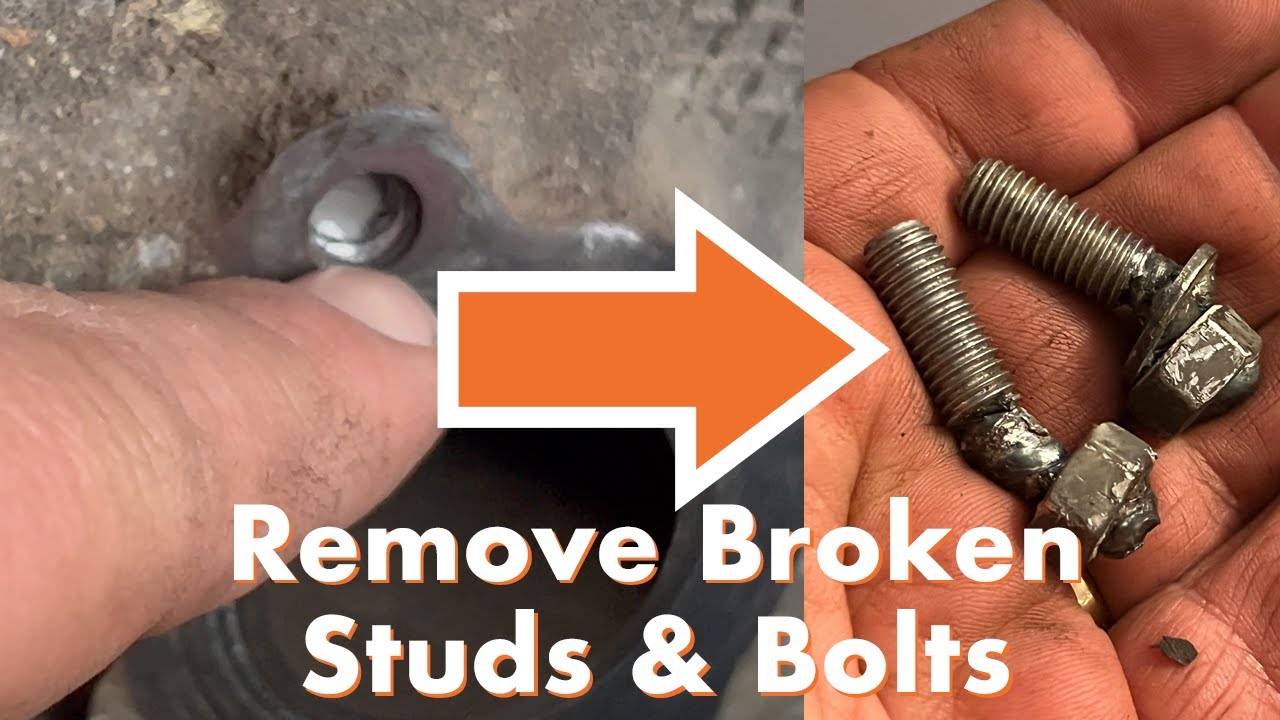

How to Remove a Broken Bolt from an Engine Block

There are a few different ways that you can remove a broken bolt from an engine block. One way is to use a drill bit that is slightly smaller than the diameter of the bolt. Another way is to use a chisel and hammer to try and break the bolt free.

If neither of these methods work, then you may need to resort to using an oxy-acetylene torch to heat up the bolt so that it expands and breaks free from the engine block.

- First, you’ll need to gather a few tools including an impact wrench, socket set, and penetrating oil

- Next, locate the broken bolt and spray it with the penetrating oil

- Allow it to sit for a few minutes to loosen up the rust and grime

- Now place the socket on the bolt head and attach the impact wrench

- Apply pressure to the wrench until the bolt begins to turn

- Once the bolt starts moving, finish removing it by hand or with a ratchet

- If the broken bolt is deeply seated in the engine block, you may need to use a drill and extraction bit to remove it completely

Credit: shop.advanceautoparts.com

How Do You Drill Out a Broken Bolt in an Engine Block?

If you’re lucky, the broken bolt will be sticking out of the engine block far enough that you can grab it with a pair of vise grips. If not, you’ll have to drill a hole into the center of the bolt so you can use an easy-out tool. First, use a center punch to make a divot in the center of the bolt head.

This will help keep your drill bit from slipping. Next, use a small drill bit to start drilling into the center of the bolt head. Keep going until your drill bit is about half as wide as the bolt itself.

Now it’s time to break out the big guns. Use a drill bit that’s slightly larger than the width of the easy-out tool you’re going to use. Drill slowly and carefully into the center of the bolt until you’ve drilled all the way through.

The goal here is to create a pilot hole for your easy-out tool so it doesn’t slip and damage either your engine block or itself.

Finally, screw in your easy-out tool until it’s flush with the surface of the engine block then give it a few good twists counterclockwise until hopefully, voila! The broken bolt should come right out.

How Do You Remove a Bolt With the Head Snapped Off?

If the head of a bolt has snapped off, it can be difficult to remove. However, there are a few methods that may work.

One method is to use a drill.

First, try to center the drill bit on the remaining part of the bolt. If the bolt is flush with the surface around it, this may be difficult. In that case, you can try drilling at an angle.

Once you have started drilling, apply some pressure and turn the drill clockwise. The goal is to create a new hole that will allow you to remove the rest of the bolt.

Another method is to use a hacksaw blade.

This will require some patience, as you will need to carefully saw through the metal without damaging anything else around it. Once you have cut through the bolt, you should be able to remove it easily.

If neither of these methods works or if you do not have access to a drill or hacksaw, you can try using pliers or a hammer and chisel.

Place the jaws of the pliers over the end of the bolt and squeeze tightly. Then, twist counterclockwise until thebolt loosens enough to remove by hand.

How Do You Remove a Broken Bolt Without an Extractor?

There are a few ways to remove a broken bolt without an extractor. One way is to use a drill bit that is slightly smaller than the diameter of the bolt and drill into the head of the bolt. Then, use a punch or chisel to drive the drill bit through the head of the bolt.

Another way is to grind off the head of the bolt with an angle grinder. Once the head of the bolt is removed, you should be able to unscrew it with a wrench or pliers.

What is the Best Tool to Remove a Broken Bolt?

There are a few different ways that you can remove a broken bolt, but the best tool to use depends on the situation. If the bolt is stuck in a difficult to reach place, then using a drill with an extraction bit might be your best option. If the bolt is only slightly damaged, then using a pair of pliers or vice grips might be able to remove it without causing any further damage.

However, if the bolt is severely damaged or rusted, then you might need to use a power drill or grinder to remove it.

Removing A Broken Bolt From A Engine Block The Easy Way

How to Remove a Seized Bolt With No Head

If you’re working on a project and come across a seized bolt with no head, don’t despair! There are several ways to remove the bolt without damaging the surrounding material.

One way is to use a torch to heat up the bolt.

This will expand the metal and hopefully break the seizure. Another method is to use an impact wrench or drill to try and loosen the bolt. If neither of these methods work, you may need to resort to drilling out thebolt.

Once you’ve removed the offending bolt, be sure to clean up any debris and apply some lubricant to prevent future seizing.

How to Remove a Broken Bolt from an Aluminum Engine Block

If you’re lucky, removing a broken bolt from an aluminum engine block is a relatively easy process. However, if the bolt is seized or the threads are damaged, it can be a real challenge. Here are some tips for removing a broken bolt from an aluminum engine block:

1. Use the right tools. A standard wrench or socket isn’t going to cut it when trying to remove a broken bolt. You’ll need something with more torque, like an impact wrench or air hammer.

2. Apply heat. If the bolt is seized, applying heat can help break it free. Use a torch or heating element and apply heat evenly around the circumference of the bolt head.

3. Use penetrating oil. This will help lubricate the threads and make it easier to remove the bolt. Apply liberally and let sit for at least 15 minutes before attempting to remove the bolt again.

4 .Strike sharply with a hammer . This method is often used in conjunction with one of the other methods above.

Place a punch or chisel on the head of the bolt and strike sharply with a hammer to loosen it up . Try not to damage the surrounding area too much .

5 Hammer drill

Another method that can be used , especially if other methods have failed , is drilling out thebolt .

How to Remove Broken Bolt Without Extractor

If you’ve ever had a broken bolt, you know how frustrating it can be. They seem to always break at the most inopportune times and are often very difficult to remove. If you don’t have an extractor on hand, there are still a few ways that you can remove a broken bolt.

One way is by using a drill. First, make sure that the drill bit is slightly smaller than the diameter of the bolt. Next, use the drill to create a pilot hole in the center of the bolt head.

Once the pilot hole has been created, slowly start drilling into the bolt head. As you drill, keep going deeper until the entire head of the bolt has been removed.

Another way to remove a broken bolt without an extractor is by using a chisel and hammer.

Start by placing the chisel on top of thebolt head at an angle so that when struck with the hammer, it will dig intothe head ofthebolt . Onceyou’ve gota good grip withthechisel , give ita few good whackswiththehammer untiltheheadofthebolt pops off .

With either method, onceyou’ve gottheheadofthebolt off ,you should then be ableto easily unscrewit fromwhatever materialitis threadedinto .

Broke Head off Bolt

If you’ve ever tried to remove a bolt only to have the head snap off, you know how frustrating it can be. Luckily, there are a few tricks you can try to remove the broken bolt and get your project back on track.

First, try using a pair of vice grips or pliers to grab onto the broken bolt and turn it counterclockwise.

If the bolt is rusted or otherwise difficult to budge, you may need to use a little WD-40 or other lubricant first. If this doesn’t work, you can try heating up the broken bolt with a torch until it’s glowing red hot. Then, use a punch or hammer to tap on the end of the bolt until it breaks loose.

Be careful not to damage any surrounding materials with the heat from the torch.

If all else fails, you may need to drill out the center of the brokenbolt and replace it with a new one. With a little patience and perseverance, you should be ableto remove that pesky broken bolt in no time!

How to Remove Broken Bolt Extractor

If you’re lucky, a broken bolt extractor will come out easily. But if it’s been in there awhile, or if it’s rusted, you may have to put some elbow grease into it. Here are some tips on how to remove a broken bolt extractor:

1. Start by spraying the extractor with penetrating oil. Let it sit for a few minutes so the oil can do its job.

2. Use a ratchet and socket to turn the extractor counterclockwise.

If it’s really stuck, try using an impact wrench.

3. If the above methods don’t work, you may need to use a drill to drill out the center of the extractor. Be careful not to damage the threads in the process.

4. Once the center of the extractor is drilled out, you should be able to remove it with pliers or a screwdriver.

Broken Bolt Removal Cost

Broken bolts can be a real pain, and removing them can be even more difficult and costly. However, there are a few things you can do to remove a broken bolt without spending too much money.

One option is to use an easy out tool.

This is a tool that is designed to remove broken bolts. You can purchase an easy out tool at most hardware stores for around $10. Simply insert the tool into the head of the broken bolt and turn it counterclockwise.

The easy out should grip the inside of the bolt so that you can easily remove it.

Another option is to use a drill bit that is slightly smaller than the diameter of the bolt. Drill into the head of the bolt until you have created a hole that goes all the way through it.

Once you have done this, you should be able to screw out the brokenbolt with ease. Be sure to wear safety goggles when using this method as bits of metal could fly into your eyes while drilling.

If neither of these methods work, your last resort would be to saw off the head of the bolt with a hacksaw.

This will take some time, but it will eventually get the job done.

How to Remove a Broken Screw

It happens to the best of us. You’re working away on a project, minding your own business, when suddenly you hit a snag. The screw you’re trying to remove is stripped, meaning the head is no longer able to grip the screwdriver.

Now you’re stuck with a broken screw that needs to be removed before you can continue.

There are a few different ways that you can go about removing a broken screw, but it will largely depend on the type of screws that you’re dealing with. For instance, if you’re dealing with wood screws, then there are special extractors that can be used to grab onto the head of the screw and pull it out.

On the other hand, if you’re dealing with machine screws, then using a drill may be your best bet.

No matter what type of screw you’re dealing with, there are some general tips that will help make removal easier. First, try using a pair of needle-nose pliers to grab onto the head of the screw.

If that doesn’t work, then use a hammer to gently tap around the perimeter of the head. This will loosen up any rust or debris that may be holding the screw in place.

Once you’ve loosened up the screw, try using an extraction tool or your drill to remove it from its hole.

With some patience and perseverance, you should be able to get that pesky broken screw out in no time!

Will Engine Run With Broken Head Bolt

If your engine has a broken head bolt, it may still run but it will not be able to generate enough power to be useful. The head gasket will also be damaged and will need to be replaced. If the head is warped, it may also need to be replaced.

In any case, it is best to have a professional mechanic take a look at your engine if you think you have a broken head bolt.

Conclusion

Assuming you don’t have the right tools to remove a broken bolt, the author suggests using a welder. First, clean off the area around the broken bolt. Then, use a welding rod to weld onto the head of the bolt.

After that, use a pair of vice grips to twist and remove the bolt.